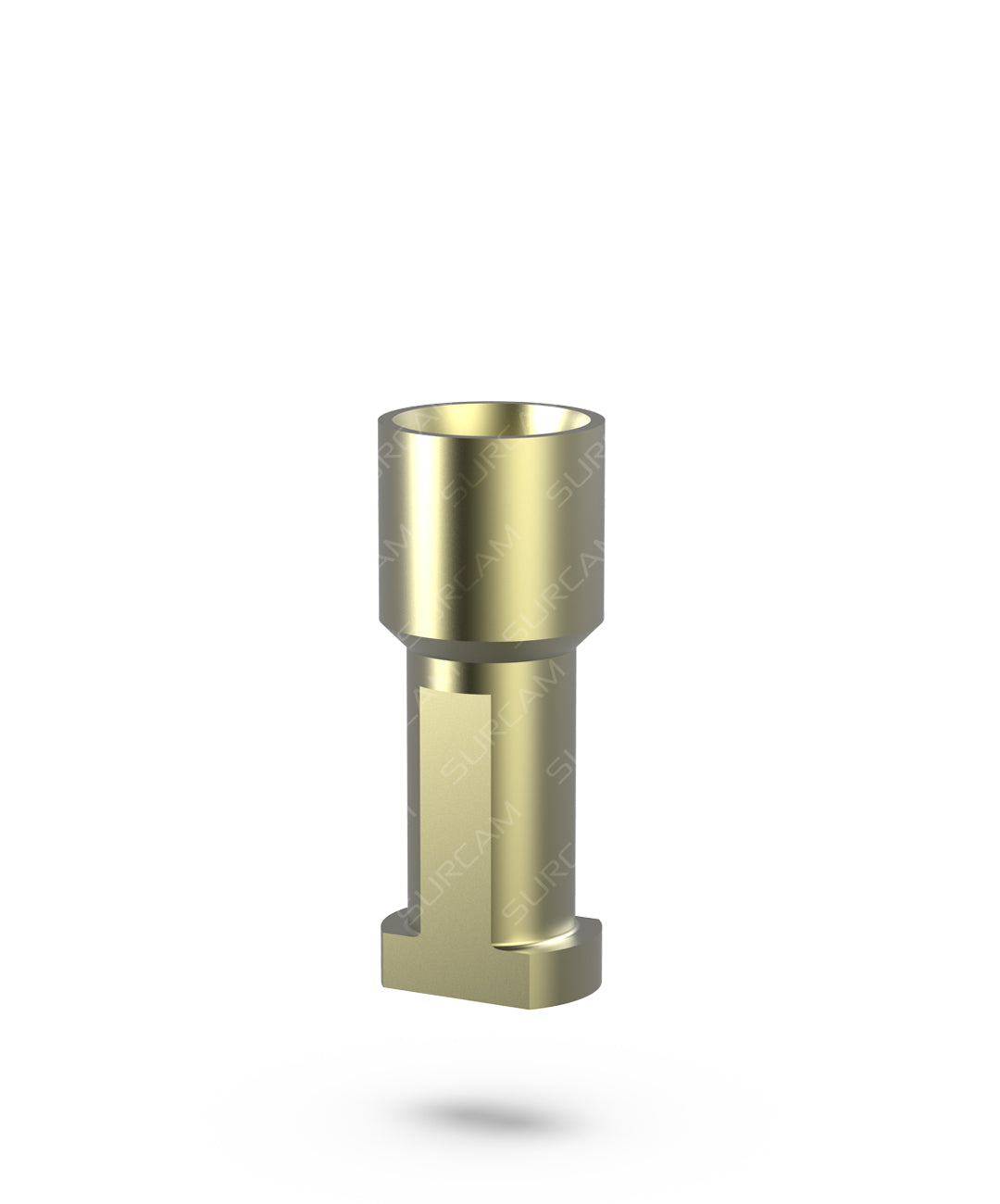

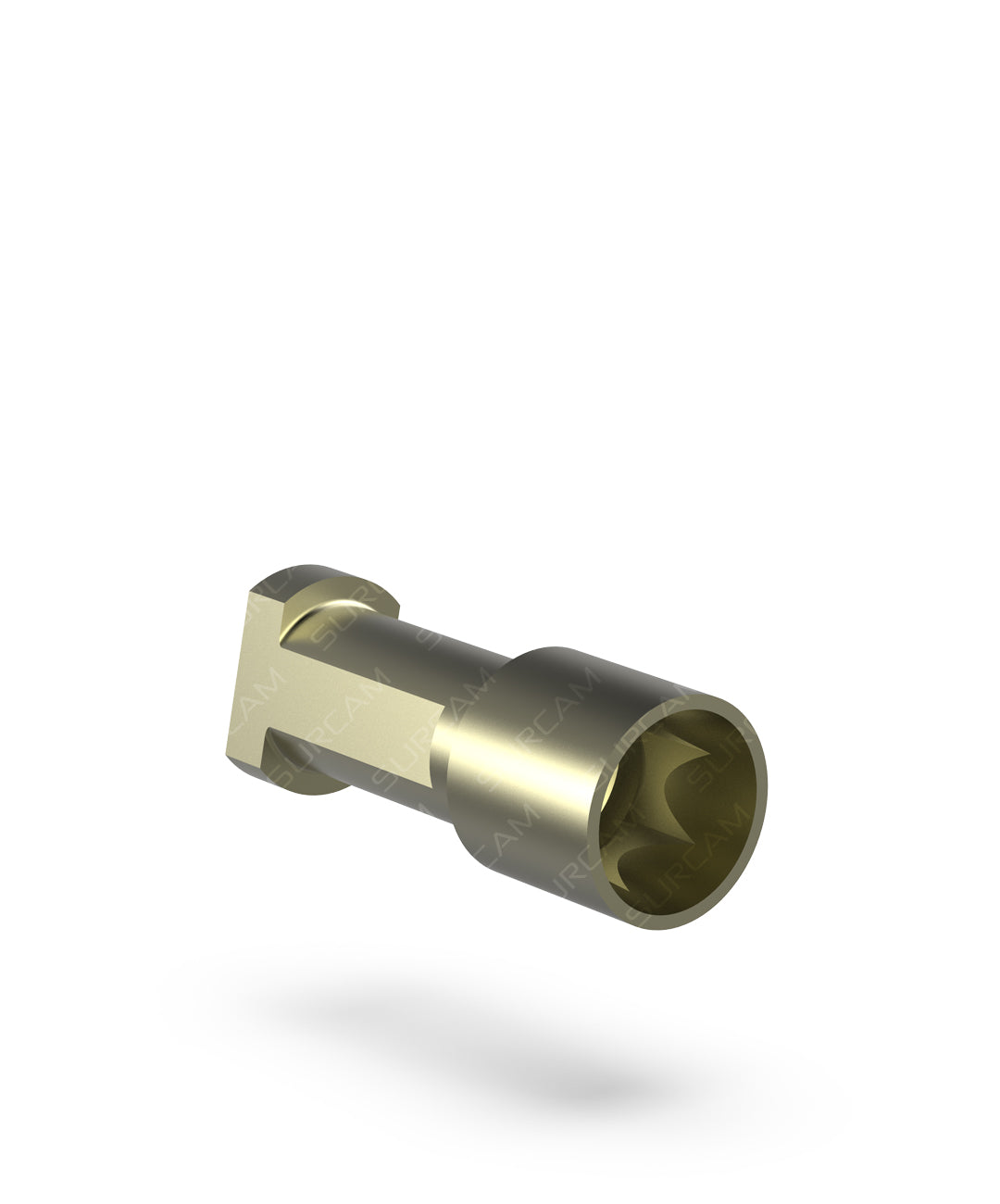

Conical Connection Casting Abutments & Copings

Waxable, cast-to, and burnout copings for custom abutments and frameworks. Platform-matched, sterile, and torque-documented

Buy Conical Connection Casting Abutments & Copings Online

Surcam’s Conical Casting Abutments & Copings let you create custom abutments and frameworks while maintaining the precision of a platform-matched conical interface. Choose burnout copings for full wax-ups or cast-to copings to combine a precision titanium base with a cast supra-structure. Each component is sterile, lot-tracked, and torque-documented, ensuring predictable seating and traceability through lab and clinical steps.

For complete case planning, pair with:

Conical Connection Implants to establish your fixture platform

Conical Transfers & Analogs for accurate impressions and model reproduction

Conical Ti-Bases (CAD/CAM) when hybrid abutment or digital workflows are indicated

Conical Healing Caps to shape tissue before final delivery

Conical Multi-Unit Abutments if converting to screw-retained solutions

Tools & Wrenches for proper torque application and maintenance logging

This collection helps you maintain prosthetic accuracy and support custom esthetic and functional outcomes while staying compliant with documentation and sterilization requirements.

Get the Right Implants, Right on Time

Order online with confidence- from single cases to bulk supply. Our team is here to help you select the right components and get them delivered fast.