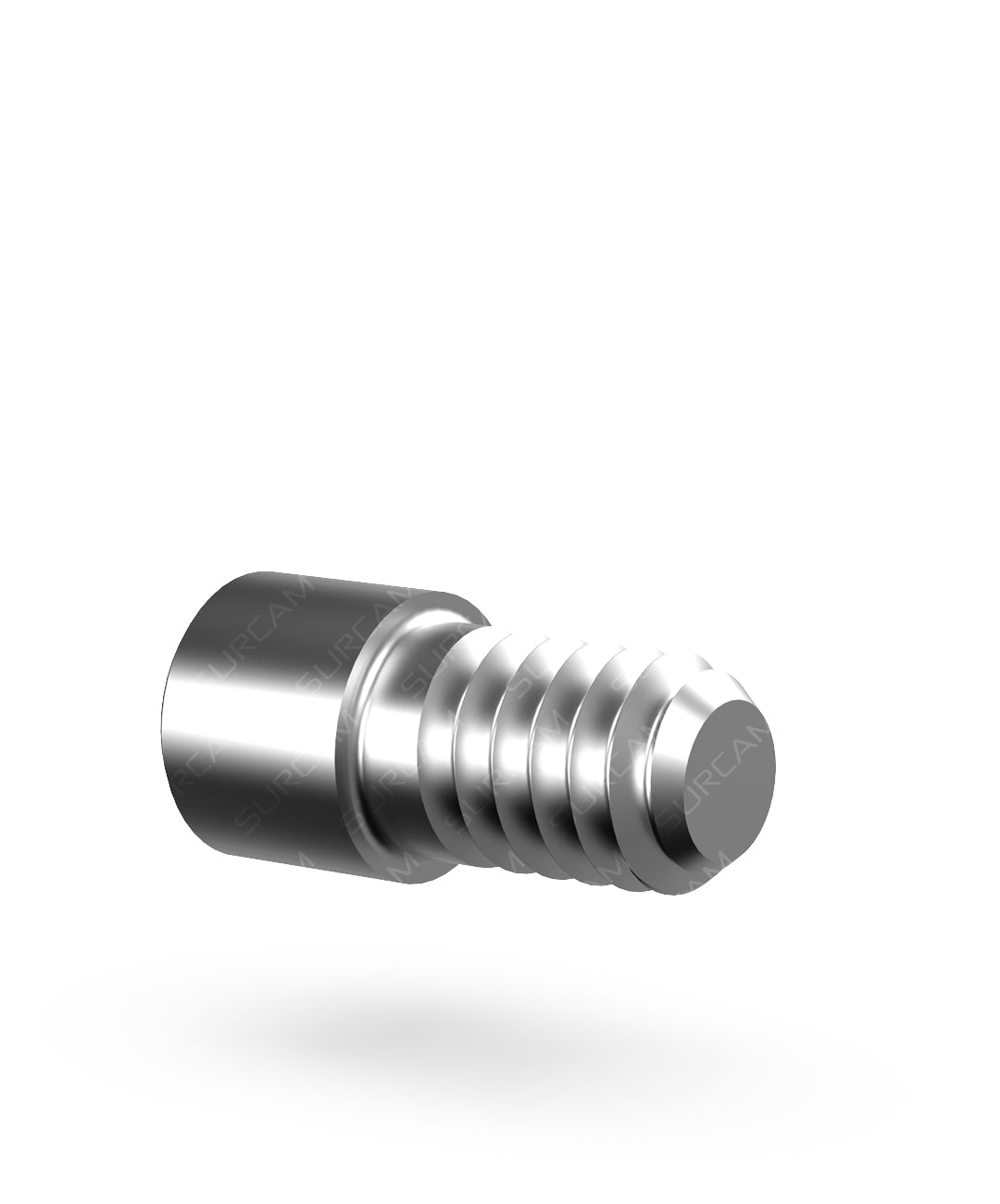

Prosthetic Screws

Prosthetic screws for dental implants engineered for secure preload, repeatable torque and precise fit. Platform matched for Surcam implants and multi units in clinic and lab workflows.

Buy Prosthetic Screws Online

How Prosthetic Screws Work in Surcam Restorative Workflows

In a screw retained restoration, the prosthetic screw is the critical link that maintains clamping force between the implant connection and the prosthesis. When tightened to the recommended torque, Surcam prosthetic screws generate controlled preload that limits micromovement at the interface, reduces screw loosening and protects the bone implant interface from overload. Every screw is platform matched to Surcam internal hex or conical connections and validated for use with our multi unit abutments and Ti base workflows.

Implant Level and Multi Unit Level Screws

Choose implant level abutment screws when restoring directly on Surcam implant fixtures and multi unit level screws when restoring on Surcam multi unit abutments for full arch or segmental bridges. Both screw families share the same principles of precise thread design, controlled preload and compatible driver interfaces for safe access in posterior and full arch cases.

Prosthetic Screws in the Surcam System

For a predictable restorative chain, match each prosthetic screw to the correct platform and component stack:

- Internal Hex Implants – use platform matched prosthetic screws with Surcam internal hex implants and prosthetic abutments.

- Conical Connection Implants – select conical prosthetic screws for conical connection prosthetic abutments.

- Multi Unit Full Arch – use multi unit specific screws with Surcam Internal Hex Multi Unit Abutments and full arch prosthetic frameworks.

- CAD CAM Restorations – combine platform matched prosthetic screws with Internal Hex Ti Bases for CAD CAM for screw retained zirconia or hybrid restorations.

- Transfers and Analogs – confirm screw compatibility with Internal Hex Transfers and Analogs so laboratory models accurately reproduce implant positions and thread engagement.

Torque, Preload and Maintenance

Surcam prosthetic screws are supplied with recommended torque values and driver interface information. Following the torque protocol is essential to achieve adequate preload while staying below the elastic limit of the material. For high load cases or bruxism patients, periodic retightening after initial settling is recommended as part of routine maintenance. If a screw is replaced, always verify platform, connection type and driver interface before seating the new component.

Clinical Safety and Documentation

Each Surcam prosthetic screw is sterile packed, lot tracked and accompanied by instructions for use and torque guidance to support documentation in regulated environments. Lot numbers can be recorded alongside implant and abutment data so the full restorative stack remains traceable throughout the life of the case.

Zimmer Biomet®, Straumann®, Nobel Biocare® and other brands are the property of their respective owners. Surcam supplies compatible prosthetic screws for Surcam systems and specified connection geometries only.

Surcam Dental provides high-strength prosthetic screws engineered for precision, durability, and long-term restorative success. Our selection includes abutment screws, multi-unit prosthetic screws, temporary fixation screws, and platform-specific dental implant screws compatible with Internal Hex and Conical Connection systems.

Manufactured from medical-grade titanium and validated under ISO 13485 and FDA-compliant processes, each screw offers exceptional torque resistance, secure seating, and reduced risk of stripping.

Designed for clinicians and labs seeking reliable performance across crowns, bridges, hybrid dentures, and All-on-4 restorations.

Get the Right Implants, Right on Time

Order online with confidence- from single cases to bulk supply. Our team is here to help you select the right components and get them delivered fast.