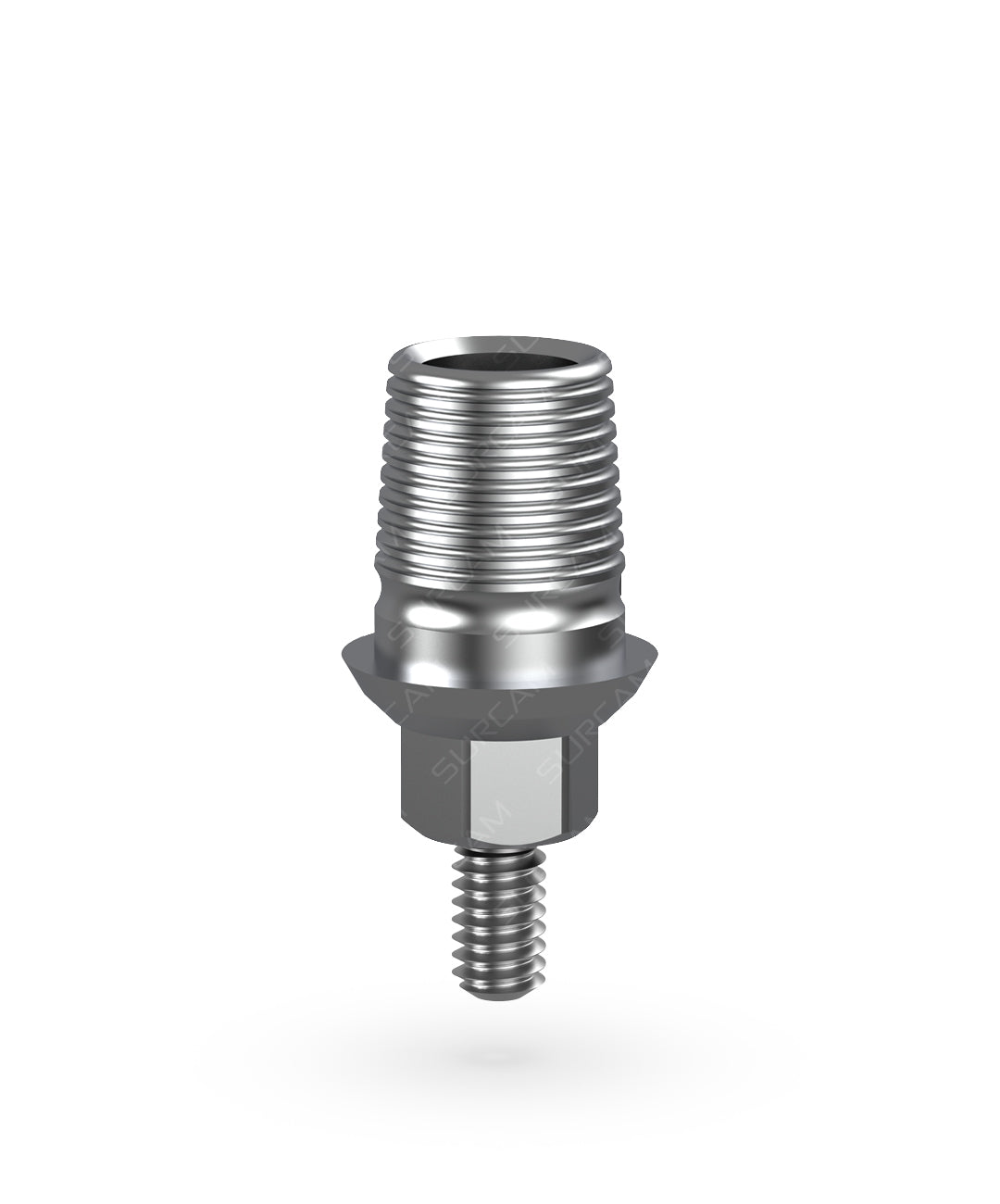

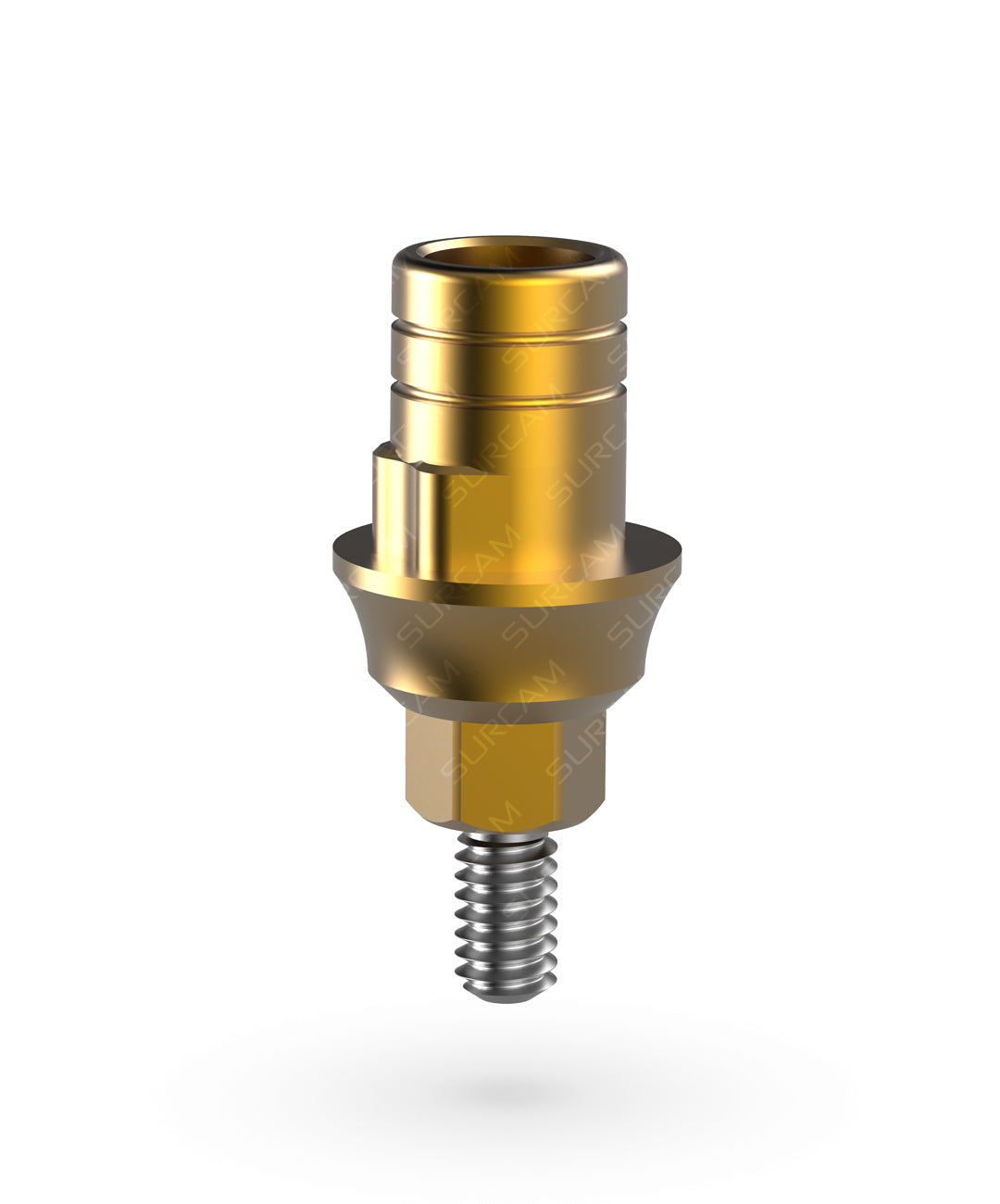

Internal Hex Ti-Base CAD/CAM

Precision-milled titanium bases for digital implant workflows. Compatible with Internal-Hex 2.42 / 2.43 mm platforms and all major CAD/CAM systems.

Buy Internal Hex Ti-Base CAD/CAM Online

When completing your digital restorative workflow, maintain perfect platform integrity by pairing Ti-Bases with other Surcam components:

Internal-Hex Dental Implants for fixture compatibility

Scan Bodies & Analogs for accurate digital or conventional impressions

Internal-Hex Multi-Unit Abutments for screw-retained bridges and hybrids

Torque Drivers & Wrenches for correct seating and long-term retention

Every component shares identical platform geometry, ensuring full cross-compatibility, repeatable torque control, and verified CAD/CAM integration.

Get the Right Implants, Right on Time

Order online with confidence- from single cases to bulk supply. Our team is here to help you select the right components and get them delivered fast.