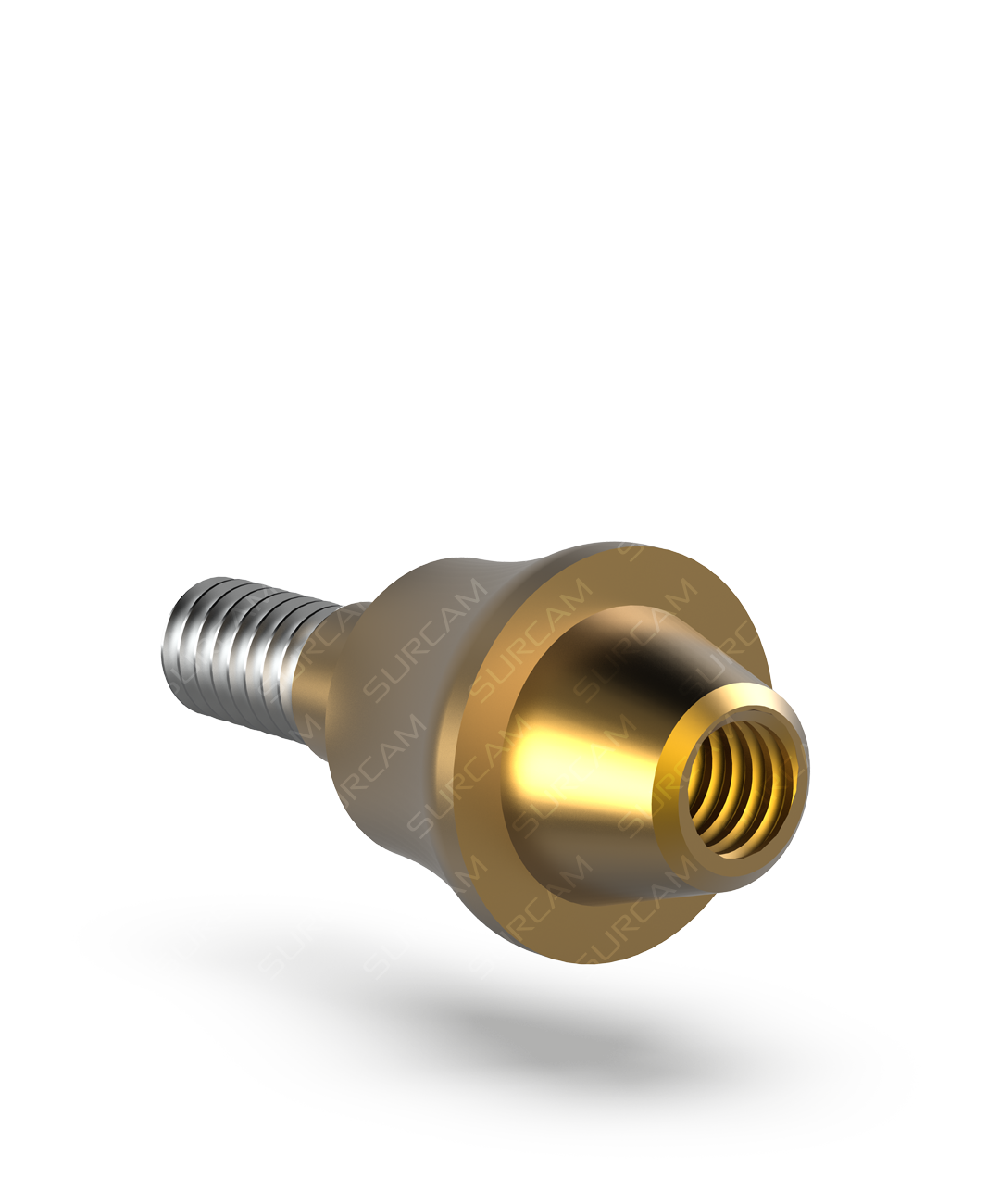

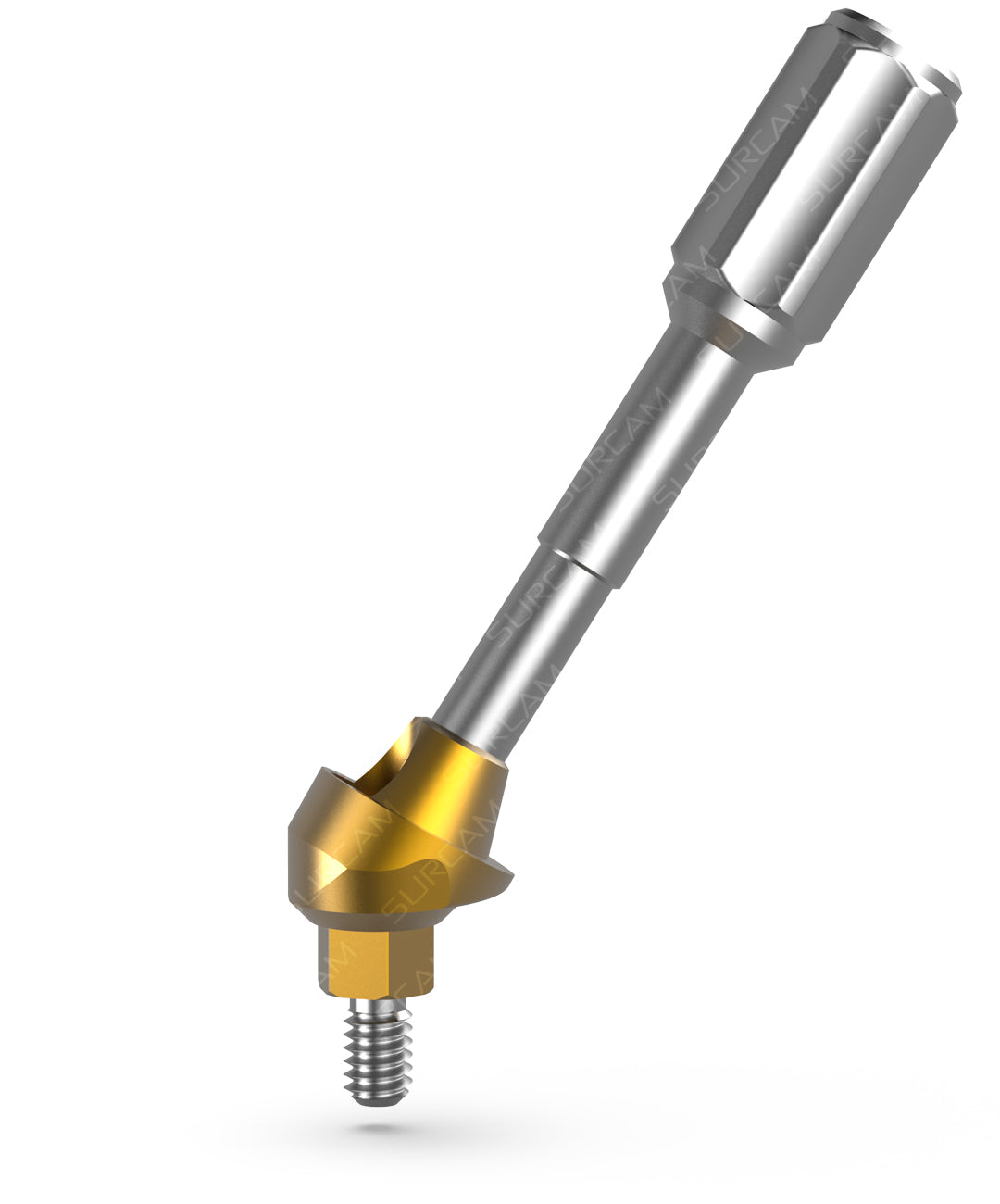

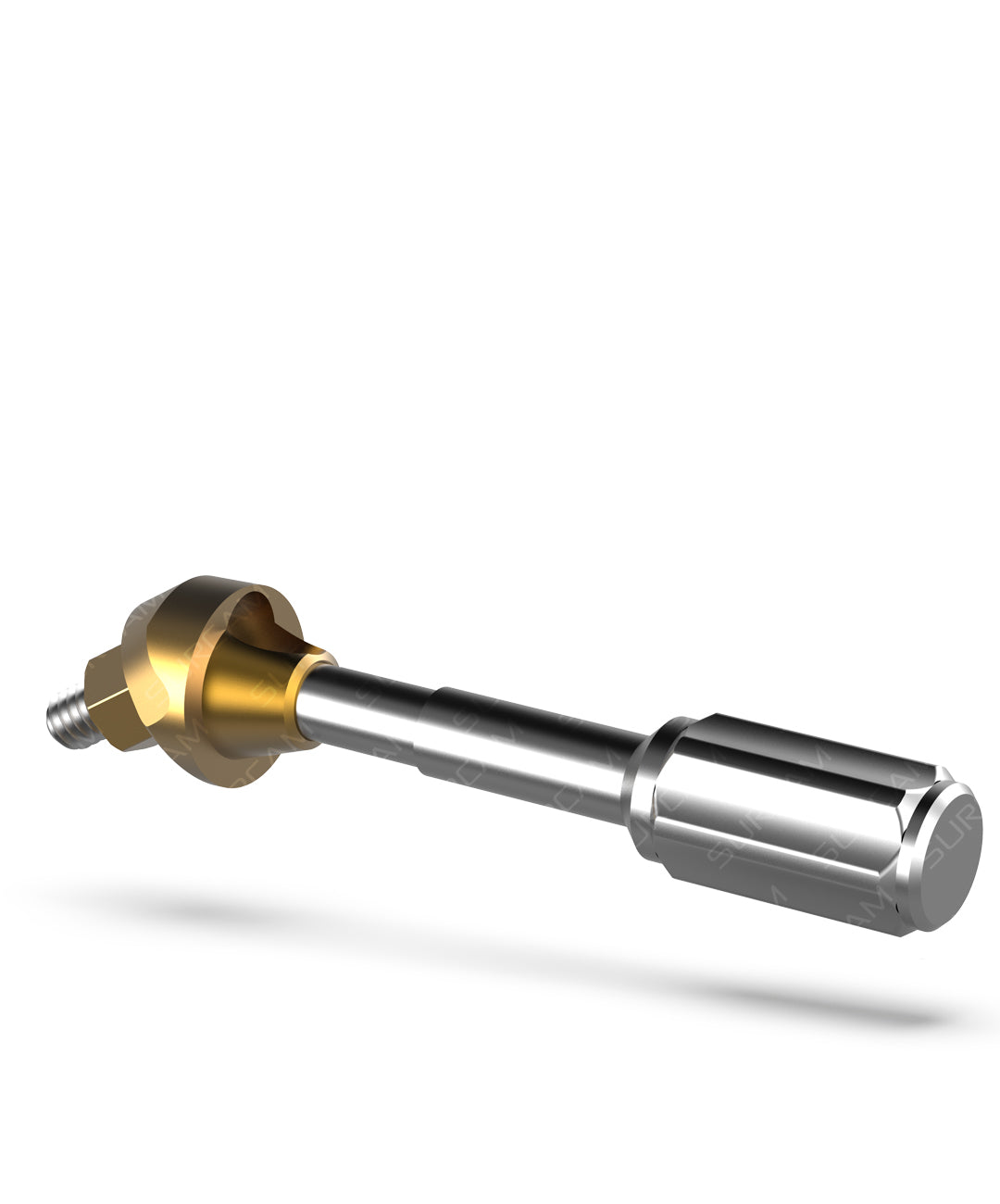

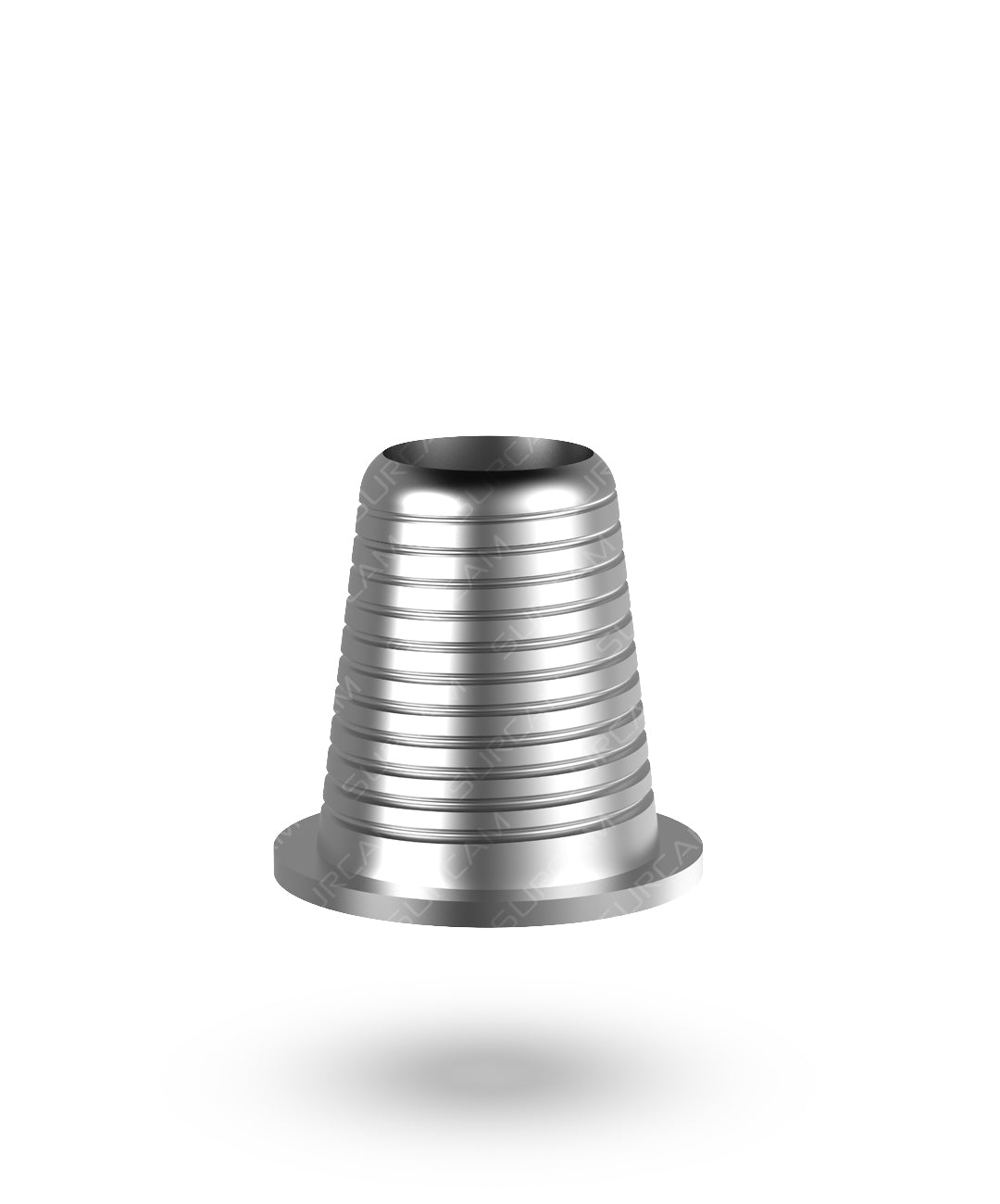

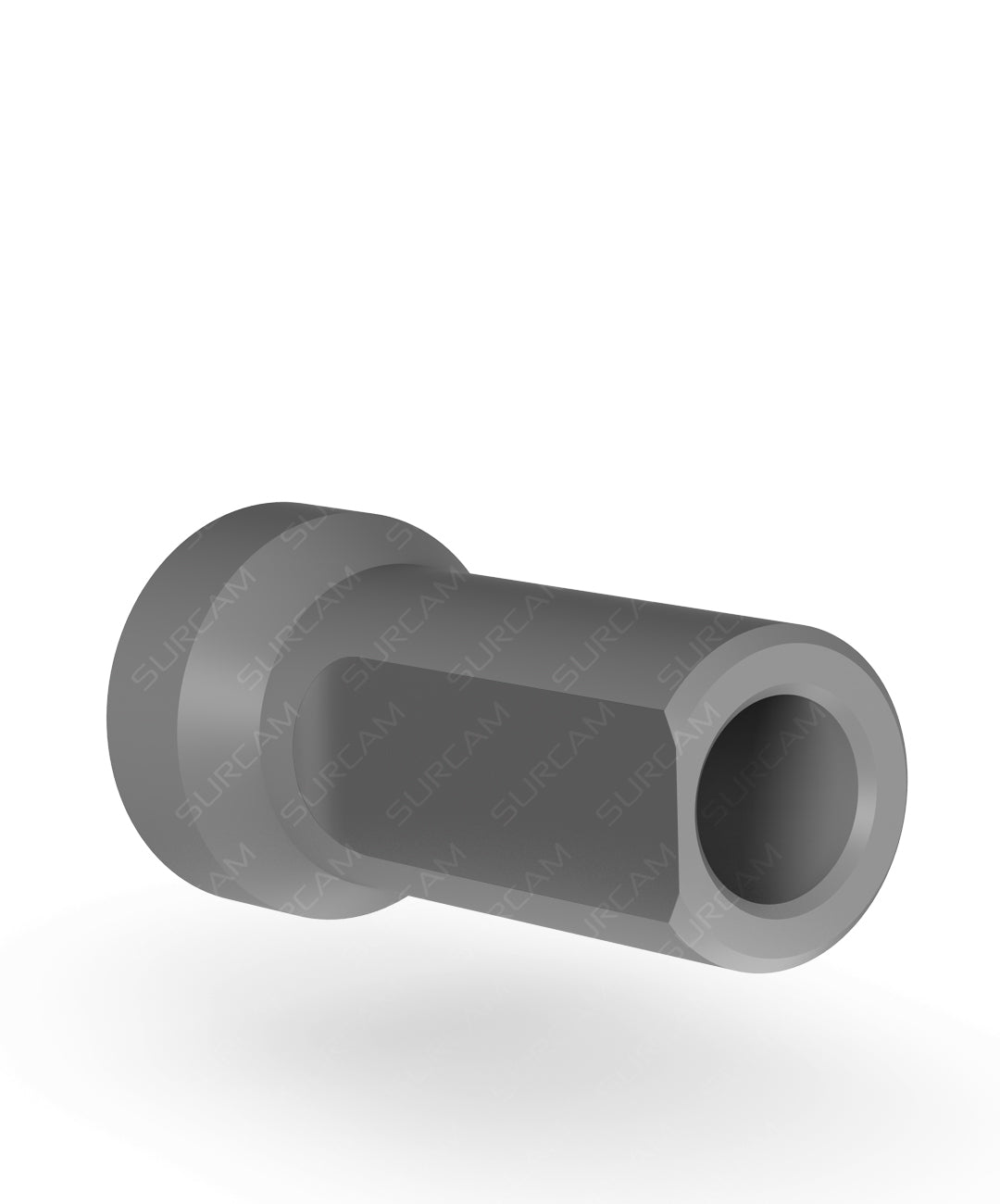

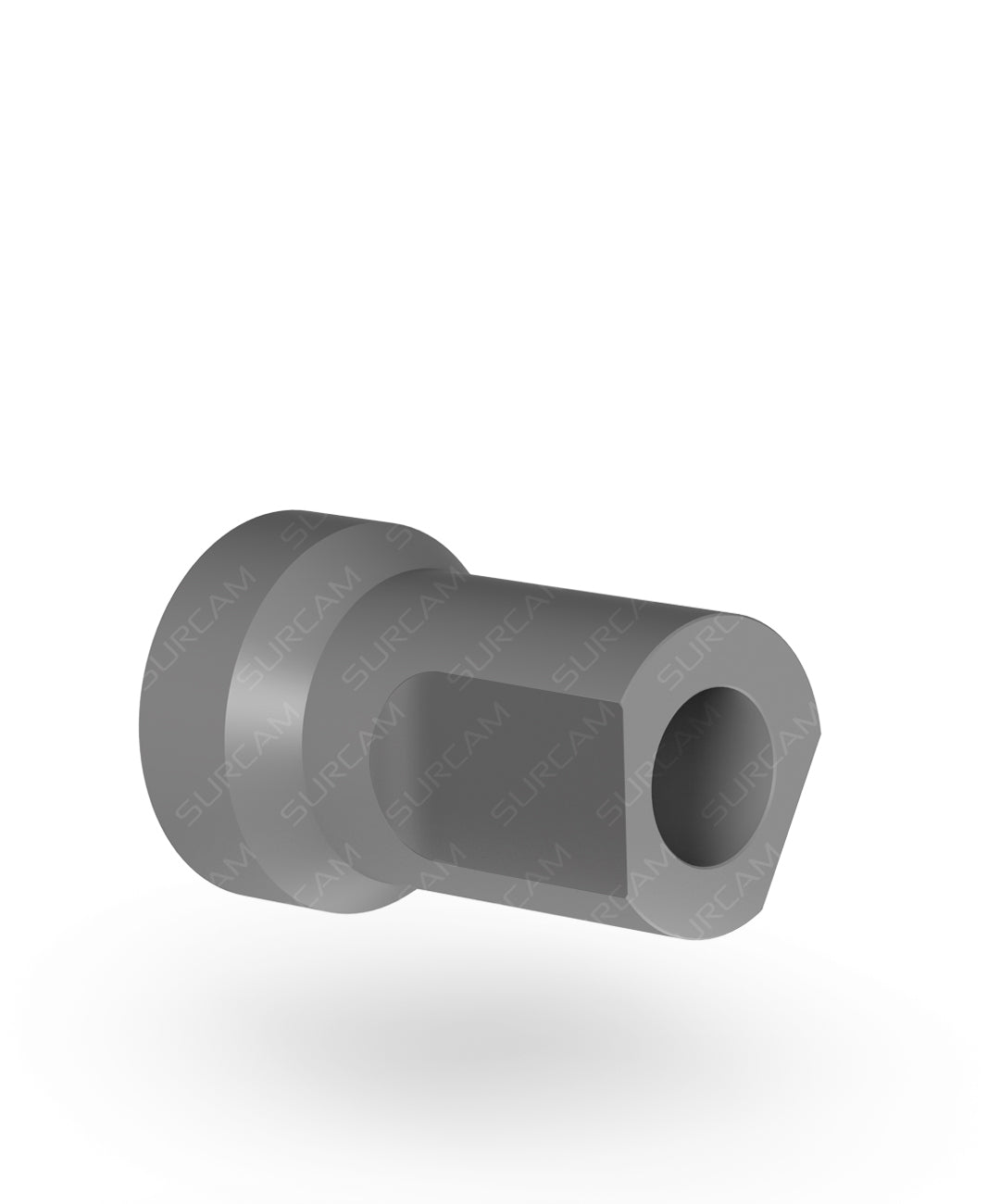

Screw-Retained Multi-Unit Abutments

Angulation correction and standardized restorative platforms for predictable screw-retained workflows.

Buy Screw-Retained Multi-Unit Abutments Online

Standardize your screw-retained workflow with Surcam’s multi-unit abutments, available in straight and angled designs with multiple cuff heights. Pair MUAs with Internal Hex Implants to create a common restorative platform for bridges and full-arch cases.

Complete the restorative stack with Transfers & Analogs, CAD/CAM Ti-Bases, and matching prosthetic screws for a fully compatible, torque-documented, and traceable solution. Each component ships sterile with lot numbers and downloadable IFUs for compliance and predictable long-term maintenance.

Get the Right Implants, Right on Time

Order online with confidence- from single cases to bulk supply. Our team is here to help you select the right components and get them delivered fast.