Product Details

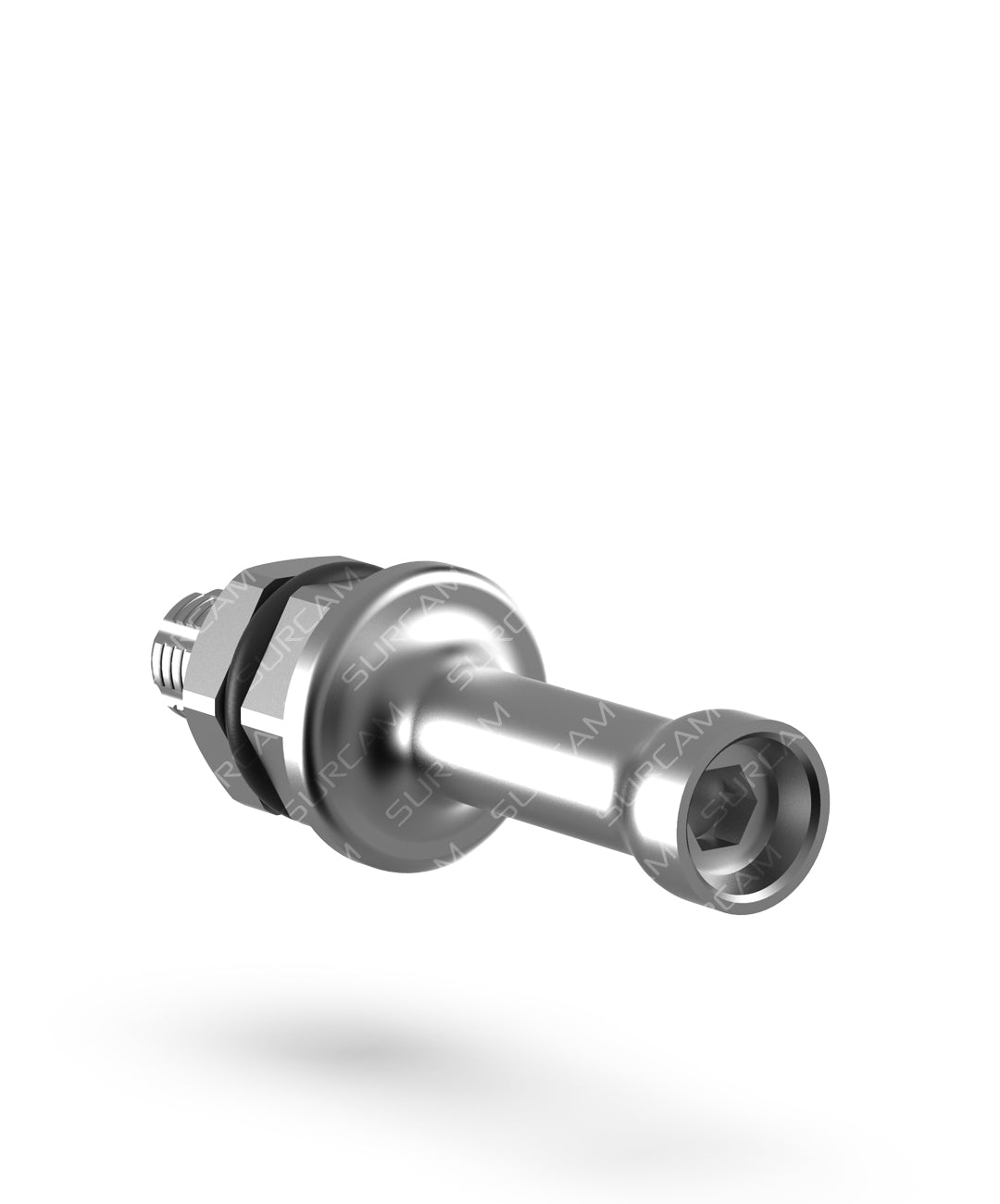

Straight driver for seating/torquing multi-unit abutments & prosthetic screws with precise fit

The Surcam Straight Multi-Unit Key is a precision driver for general Multi-Unit systems, engineered to seat and torque multi-unit abutments and prosthetic screws with a stable, wobble-free fit. Its straight, slim shank improves access in posterior regions and limited interocclusal space, helping you deliver passive, screw-retained frameworks with confidence. The key interfaces with your driver handle or torque device per system IFU and is autoclavable for routine clinical re-use.

Benefits

-

Accurate engagement — Crisp fit minimizes cam-out and screw head damage.

-

Chairside efficiency — Smooth pickup/removal of Multi-Unit components.

-

Access in tight spaces — Straight, slim profile for posterior sites.

-

Reliable torque transfer — Supports consistent seating per system IFU.

-

Autoclavable — Built for daily clinical sterilization cycles.

Product Details

-

Type: Straight Multi-Unit driver/key (general Multi-Unit system)

-

Use Cases: Seating/torquing Multi-Unit abutments, prosthetic screws, cylinders (per system IFU)

-

Pack Contents: 1× Straight Multi-Unit Key

-

Compatibility: Surcam General Multi-Unit system and other compatible Multi-Unit interfaces (verify geometry and size before use)

Specifications

-

Torque: Apply values specified by the implant/Multi-Unit system IFU

-

Sterilization: Autoclave according to clinic protocol and device IFU

-

Technique: Ensure full seating and axial alignment prior to torqueing

-

Notes: Always verify driver interface size/shape with the component manufacturer before clinical use

Why Choose Surcam Drivers?

-

Consistent fit and feel for predictable torque delivery

-

Helps reduce stripped screws and remakes

-

Designed for daily clinical use and repeat sterilization

Surcam Drivers FAQs

Which Multi-Unit systems are compatible?

General Multi-Unit interfaces that match this driver’s geometry. Always verify driver size/shape against your abutment/screw manufacturer’s specifications before use.

Can I use this key with angled Multi-Unit abutments?

Yes—if the interface geometry is the same. Confirm fit on the specific angled or straight Multi-Unit component prior to clinical torqueing.

What torque should I apply?

Follow the implant/Multi-Unit system IFU for abutment and prosthetic screw torque values. Do not exceed manufacturer specifications.

How do I avoid cam-out or screw damage?

Ensure full seating and axial alignment, use a calibrated torque device, and maintain clean, undamaged driver tips and screw heads.

How should I sterilize the key?

Process via autoclave per your clinic’s sterilization protocol and the device IFU before each patient.