Understanding Dental Implant Compatibility

- by Shay ben shabat

Understanding Dental Implant Compatibility – Materials, Patients, and Prosthetic Fit

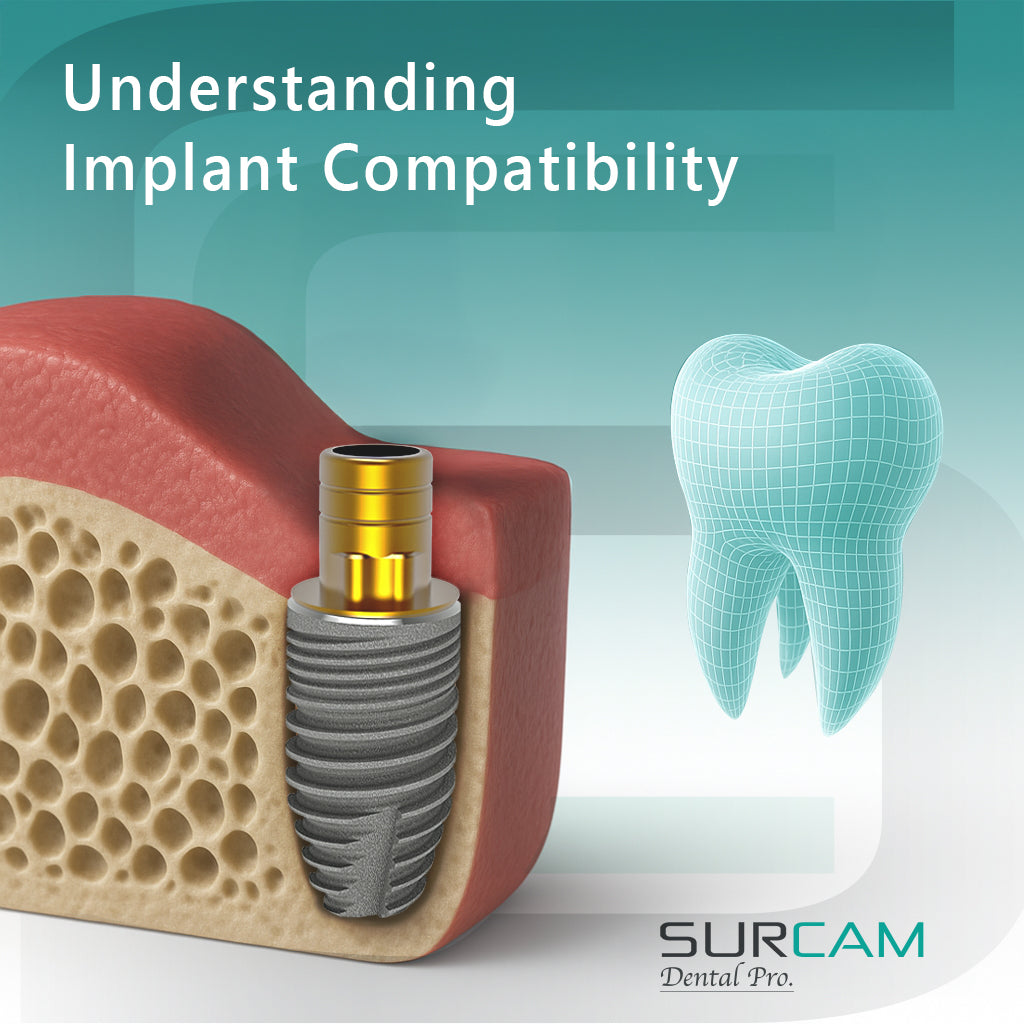

What Is Dental Implant Compatibility?

Dental implant compatibility is the ability of an implant system to function in complete harmony with the body and with every restorative component used in treatment. A compatible dental implant must meet biological, mechanical, and digital standards that allow it to integrate safely and perform predictably.

Three Dimensions of Implant Compatibility

Biocompatibility

The implant material must be accepted by the body and support direct bone attachment through osseointegration. Titanium and zirconia implants are the most widely used because they are biocompatible, corrosion resistant, and promote bone growth at the interface. Surcam’s Grade 5 titanium and SLA-treated surfaces provide proven biological acceptance and long-term tissue stability.

Patient Suitability

Implant success depends on the condition of the patient’s oral and systemic health. Healthy bone density, controlled medical conditions, and proper hygiene all contribute to implant stability and long-term success[1].

Prosthetic and System Compatibility

Every component in the implant system, from the implant fixture and abutment to the final restoration, must fit with verified precision. Mixing parts from different manufacturers often leads to poor alignment, microgaps, or bacterial infiltration. Surcam Dental ensures precise implant abutment connection geometry across all Internal Hex and Conical Connection platforms for consistent torque values and mechanical fit.

When an implant system is fully compatible, the implant behaves like a natural tooth root. It restores chewing strength, maintains jawbone density, and supports long-term esthetics. Clinicians benefit from smoother workflows and fewer prosthetic complications. To learn more, explore Surcam’s Internal Hex Components and Conical Connection Components.

Advantages of Compatible Dental Implants

Compatible dental implants provide clinical, biological, and functional advantages that set them apart from conventional restorations. When every implant component, from the fixture to the abutment and crown, fits with verified precision, the result is long-term stability and natural function.

Key Benefits of Compatible Implants

Improved Stability and Osseointegration

A compatible implant system ensures that bone cells attach firmly to the implant surface. This biological connection, called osseointegration, creates root-level stability and eliminates the shifting or movement often seen with dentures or poorly fitted restorations.

Preservation of Bone and Soft Tissue Health

Dental implants stimulate the jawbone and prevent bone loss, maintaining facial structure and gingival contours. Compatibility between implant and abutment minimizes micro-movement and bacterial leakage, reducing the risk of peri-implantitis and soft tissue recession.

Long-Term Durability

Implant systems manufactured from Grade 5 titanium or high-density zirconia resist corrosion and fatigue, providing a long-lasting foundation for prosthetic restorations. When properly maintained, compatible implants can remain functional for decades with minimal need for replacement.

Enhanced Chewing Power and Function

Because of their mechanical precision, compatible implant systems distribute chewing forces evenly along the bone. Patients experience stable biting performance and the freedom to enjoy a full range of foods without discomfort or slippage.

Predictable Clinical Outcomes

For clinicians, implant system compatibility translates to efficiency and reduced chair time. When the implant, abutment, and digital workflow are perfectly aligned, prosthetic seating is predictable, torque values are consistent, and maintenance is simplified.

Surcam Dental designs every system for precise implant-abutment engagement, optimized load distribution, and verified ISO/FDA compliance. Explore the range of Internal Hex Dental Implants and Screw-Retained Multi-Unit Abutments.

Biocompatibility – How Implant Materials Interact with the Body

Biocompatibility refers to how well an implant material integrates with living tissues without causing an adverse biological reaction. In dental implantology, this means the body must accept the implant as its own, allowing new bone to attach directly to the implant surface through osseointegration.

A truly biocompatible implant material promotes healthy tissue attachment, minimizes inflammation, and maintains long-term stability under load.

Titanium – The Gold Standard for Implant Success

Titanium remains the most widely used material for dental implants because it combines high strength, corrosion resistance, and excellent biological tolerance[2]. Its natural oxide layer supports direct bone contact, enabling stable osseointegration.

At Surcam Dental, all fixtures are manufactured from Grade 5 Ti-6Al-4V ELI titanium, chosen for its superior fatigue resistance and compatibility with human bone. Our SLA surface treatment (Sandblasted, Large-grit, Acid-etched) increases microscopic surface area, improving initial bone attachment and accelerating healing.

Zirconia – A Metal-Free Alternative

Zirconia implants provide a metal-free solution for patients with sensitivity concerns or high esthetic demands. Their white color blends naturally with soft tissues and offers excellent biocompatibility. Although long-term data is still expanding, zirconia demonstrates favorable bone integration and tissue health in anterior and cosmetic applications.

Surface Coatings and Tissue Response

Beyond material composition, surface science plays a critical role in biological success. Surcam Dental employs PVD titanium nitride (TiN) coatings on transmucosal and prosthetic components to improve surface hardness, reduce bacterial adhesion, and enhance torque retention[3]. The warm gold tone of TiN also provides an esthetic advantage under thin gingiva.

Each implant system undergoes ISO and FDA-certified testing for cytotoxicity, corrosion resistance, and surface topography to ensure biological safety. Surcam’s Prime Series TiN technology strengthens abutment longevity and soft tissue performance. Learn more about Prime Series Multi-Unit Abutments and Conical Connection Implants.

Patient Suitability – Determining Clinical Success

Patient suitability for dental implants refers to the clinical evaluation of whether a person’s oral and systemic health can support a stable and long-lasting implant. Even the most advanced implant system relies on the right biological foundation for success.

Key Factors for Implant Candidacy

Bone Volume and Density

Healthy bone is essential for achieving primary stability and long-term support. Patients with low bone density may require bone grafting or sinus augmentation before implant placement. CBCT imaging helps assess bone quality and angulation for optimal positioning.

Oral Health Status

The mouth must be free of active infection before implant surgery. Conditions such as periodontitis, untreated decay, or mucosal inflammation increase the risk of implant failure and peri-implantitis. Comprehensive oral hygiene and regular professional maintenance are mandatory for sustained success.

Systemic Health and Healing Capacity

Certain conditions influence healing and osseointegration. Diabetic patients, individuals with compromised immunity, or those taking bisphosphonates must be carefully managed. When systemic diseases are well controlled, implant success rates approach those of healthy patients.

Lifestyle and Habits

Smoking, poor diet, and inconsistent oral care significantly increase the likelihood of bone loss and delayed healing. Encouraging patients to stop smoking prior to surgery greatly improves implant survival rates.

Digital Diagnostics and Planning

Modern evaluation combines 3D CBCT scans, intraoral scanning, and guided surgery protocols to ensure precise angulation and prosthetic alignment. Digital planning improves both esthetic and functional outcomes.

Patient selection remains one of the most important predictors of implant longevity. Surcam Dental supports clinicians with restorative systems and diagnostic tools that adapt to diverse bone conditions and patient needs. Explore Surgical Tools and Wrenches and Internal Hex Transfers and Analogs.

Prosthetic Component Compatibility

Prosthetic component compatibility ensures that every part of a dental implant system—implant fixture, abutment, screw, and restoration—works together seamlessly. Achieving a precise fit across these elements guarantees mechanical stability, prevents microleakage, and supports long-term biological integration.

Implant System Design and Alignment

Each implant brand is engineered with unique internal geometries and manufacturing tolerances. Components from different systems may vary in thread engagement, wall thickness, or seating depth. These variations can cause micromovement or bacterial infiltration when mixed[4]. Surcam Dental’s verified Internal Hex (2.42 mm) and Conical Connection (11° Morse taper) interfaces are produced under ISO-certified manufacturing standards for a precise, repeatable fit and optimal torque stability.

Cross-Platform Precision and Clinical Value

While same-brand connections typically ensure the highest precision, many clinics manage multiple implant systems. Surcam Dental’s prosthetic components are cross-compatible with major global platforms such as Zimmer, MIS, Alpha-Bio, Implant Direct, and Nobel Biocare. This approach maintains prosthetic reliability while offering clinicians improved cost efficiency and streamlined inventory control.

Material and Connection Compatibility

Surcam’s abutments and prosthetic components are made from Grade 5 titanium (Ti-6Al-4V ELI), known for exceptional strength, fatigue resistance, and corrosion protection. For anterior and esthetic cases, zirconia abutments offer high translucency and tissue-friendly properties. Both materials are tested for hardness, wear, and torque retention to guarantee durability and biological harmony.

Connection geometry defines how forces are transferred through the implant system. Surcam provides solutions for the three most common types:

- Internal Hex Connection – Reliable anti-rotation and cross-system flexibility.

- Conical Connection (Morse Taper) – Friction-fit design that reduces micromovement and enhances bone preservation.

- External Hex Connection – Supported for compatibility with legacy systems still used in clinical workflows.

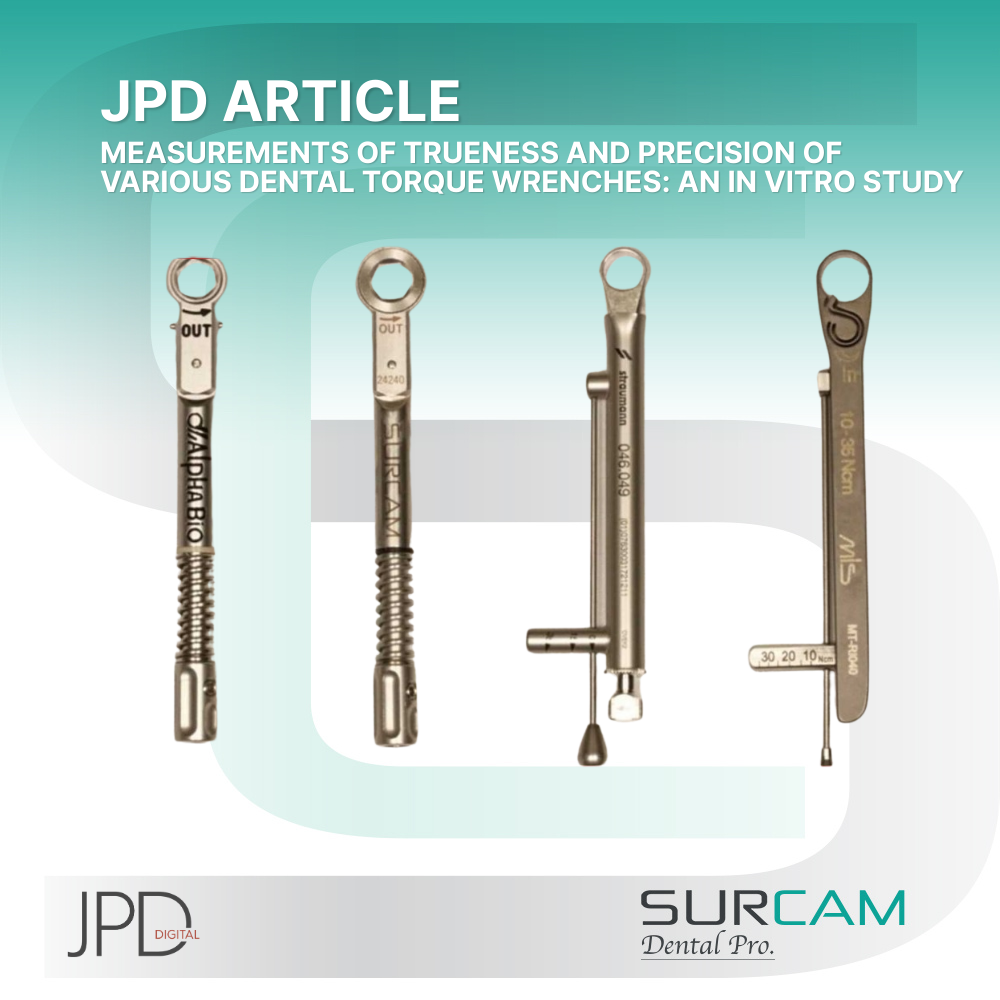

Tools, Drivers, and Workflow Integration

Prosthetic and surgical tools must match the implant platform to ensure torque accuracy. Using the wrong driver or wrench can distort torque preload and compromise fit. Surcam’s precision-calibrated drivers and torque tools maintain accurate mechanical performance and protect internal interfaces across all systems.

Surcam Dental unites these mechanical and material principles to create a consistent, dependable prosthetic ecosystem. Learn more about Internal Hex Components and Conical Connection Components.

Digital Compatibility – CAD/CAM and Guided Surgery Integration

Digital compatibility refers to how accurately an implant system integrates with modern design and manufacturing tools in restorative dentistry. A digitally compatible implant allows seamless communication between clinical scans, CAD software, and CAM milling or 3D printing systems.

Digital Workflow Integration

When digital data matches implant geometry, clinicians achieve faster workflows, improved prosthetic precision, and fewer chairside adjustments.

Scan Bodies and Digital Libraries

Scan bodies record implant positioning and must reflect exact internal geometry for accurate restoration design. Surcam Dental scan bodies are verified for precision and fully compatible with CAD systems such as Exocad, 3Shape, Dental Wings, and Zirkonzahn. Digital libraries replicate Surcam’s Internal Hex and Conical Connection geometries for consistent seating and angulation.

Ti-Bases and Digital Analogs

Ti-bases connect CAD-designed restorations to the implant or abutment. Surcam’s CAD/CAM Ti-bases and digital analogs reproduce implant geometry with exact tolerances, ensuring predictable seating whether restorations are printed, milled, or cast. Explore Internal Hex Ti-Bases and Conical Connection Ti-Bases.

Guided Surgery and Workflow Precision

Digital compatibility extends to guided implant surgery. CBCT-based planning software translates treatment plans into surgical templates that control depth, angle, and positioning. Surcam Dental integrates guided surgery tools, digital libraries, and CAD/CAM restorations into a continuous workflow that improves esthetics, load distribution, and clinical precision.

Digital integration transforms implantology into a data-driven process that enhances accuracy, speed, and predictability. Surcam Dental’s open-system design connects every digital and clinical stage, enabling clinicians to work with their preferred planning software while maintaining consistent restorative outcomes.

What to Discuss with Your Dentist or Lab Before Getting Dental Implants

Before beginning implant treatment, it is important to understand every factor that influences the long-term success of your restoration. A productive consultation between the clinician, laboratory, and patient ensures that the chosen implant system meets both biological and prosthetic requirements.

Key Discussion Points

Material Selection

Ask your dentist which implant material is best suited to your case. Titanium implants are the standard for strength and biocompatibility, while zirconia implants offer a metal-free, esthetic alternative. Surcam Dental manufactures both materials with verified osseointegration performance and long-term tissue stability.

Implant System and Connection Type

Confirm which implant platform your clinic uses and whether all components come from a verified manufacturer. Surcam’s Internal Hex and Conical Connection systems are compatible with leading global platforms, providing predictable results and cost-effective flexibility.

Digital Workflow and Laboratory Coordination

Ask if your treatment will include CAD/CAM fabrication or guided surgery planning. Surcam’s digital ecosystem ensures compatibility across Exocad and 3Shape libraries, delivering precise prosthetic fit and alignment.

Maintenance and Follow-Up

Establish a long-term care plan including hygiene appointments and torque checks. Regular follow-up maintains bone health and prosthetic stability. Learn more about Surcam Dental Implant Systems to see how precision design supports clinical longevity.

Compatibility as the Core of Reliability

The Foundation of Predictable Results

Dental implant compatibility is more than a technical feature; it is the foundation of every successful restorative outcome. A compatible implant system ensures that every component, from the fixture and abutment to the final restoration, works as one precise and biologically stable unit.

Why Compatibility Matters for Long-Term Success

Compatibility protects peri-implant bone and soft tissue, maintains even load distribution, and reduces the risk of screw loosening or bacterial leakage. When mechanical precision and biological integration align, implants perform with natural function and durability. For patients, this means long-term comfort, confidence, and improved esthetics.

Surcam Dental’s Engineering Commitment

At Surcam Dental, compatibility is integrated into every design and manufacturing stage. Our implants, abutments, and restorative components are produced with micron-level accuracy and verified under ISO and FDA standards. Both Internal Hex and Conical Connection systems are developed for cross-brand mechanical compatibility with leading global platforms such as Zimmer, MIS, Alpha-Bio, and Nobel Biocare. This ensures flexibility, reliability, and measurable clinical value across diverse workflows.

Built for Consistency, Precision, and Trust

Surcam Dental combines advanced surface treatments, digital integration, and complete restorative solutions to provide consistent results across all procedures. Whether restoring a single tooth or a full arch, each system delivers the strength, esthetics, and precision that define modern implantology.

Explore Surcam Dental Implant Systems to experience verified compatibility and lasting clinical confidence.

References

- ^ American Dental Association. Learning About Your Gums. ADA Library, 2025.

- ^ Galindo-Moreno P, et al. Marginal bone loss around implants with internal hexagonal and conical connections: randomized study. NIH/PMC, 2021.

- ^ Effect of duplex treatment on the long-term stability of the abutment-implant interface by plasma nitriding and TiN coating. Surface & Coatings Technology, Elsevier, 2022.

- ^ Rodrigues VVM, et al. Internal conical vs non-conical connections: systematic review and meta-analysis. J Prosthodont, 2023.

- Posted in:

- Educational