Dental Torque Wrench Accuracy: Friction vs Spring Designs

- by Shay ben shabat

Summary

Independent laboratory data published in a leading prosthodontic journal showed that Surcam’s friction-style torque wrench delivered more accurate and consistent torque than spring-style devices tested. Including those from top global implant manufacturers. For clinicians focused on precision and prosthetic reliability, torque accuracy matters.

Dental Torque Wrench Accuracy: Evidence From Independent Research

Why Torque Accuracy Is Clinically Critical

Accurate torque delivery is essential for dental implants prosthetics. Under-torquing may result in screw loosening and micromovement, while over-torquing increases the risk of screw deformation or fracture. Even small deviations from the recommended torque value can compromise the long-term stability of implant-supported restorations.

What the Study Evaluated

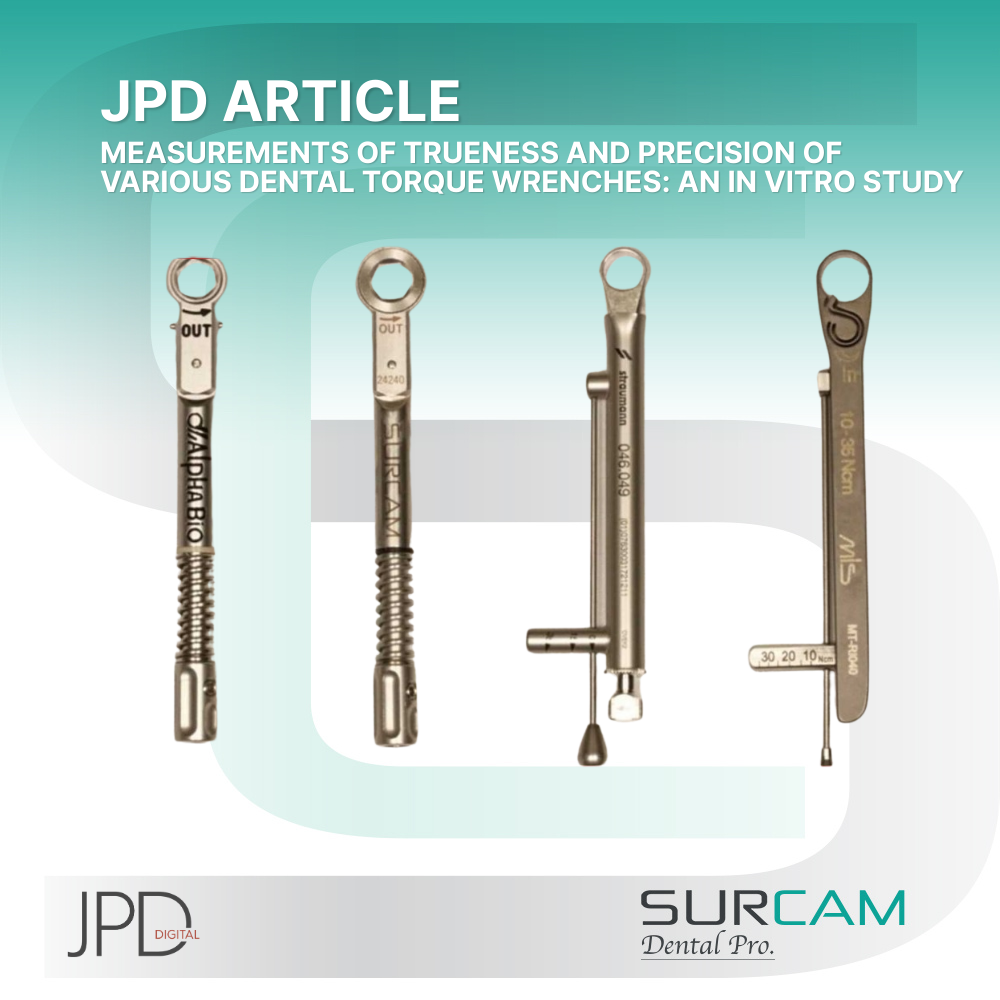

A recent independent in-vitro study published in the Journal of Prosthetic Dentistry evaluated the trueness and precision of dental torque wrenches from four manufacturers, comparing spring-style and friction-style designs under standardized laboratory conditions.

The study tested torque wrenches from MIS Implant Technologies and Institut Straumann AG (spring-style), and from Alpha-Bio Tec and Surcam Dental Pro (friction-style).

Key Results: Surcam Demonstrated Superior Consistency

Across all tested devices, torque deviations ranged from –0.7 to 3.8 Ncm, with precision values between 0.2 and 1.5 Ncm.

However, a clear performance difference emerged:

-

Spring-style torque wrenches showed significantly greater variability between measurement sessions, with deviations reaching up to 4.5 Ncm

-

Friction-style torque wrenches, including Surcam, maintained lower deviations (up to 2.5 Ncm) and higher precision

-

The Surcam torque wrench consistently delivered torque values closer to the preset target, with stable performance across repeated measurements

Within the limits of this laboratory evaluation, Surcam demonstrated superior torque accuracy and repeatability compared with spring-style devices from leading implant brands.

Clinical Relevance

Greater torque trueness and precision may help reduce:

-

Prosthetic screw loosening

-

Component fatigue

-

Mechanical complications in screw-retained restorations

This is particularly important when working with:

-

Multi-unit abutments

-

Prosthetic screws

-

Full-arch restorations

-

High-load posterior cases

Reliable torque delivery is not an accessory detail it is a mechanical safeguard for prosthetic longevity.

Explore Related Products

Read the Full Peer-Reviewed Article

For full methodology and statistical analysis, read the original publication in the Journal of Prosthetic Dentistry:

🔗 https://www.thejpd.org/article/S0022-3913(25)00539-6/abstract

- Posted in:

- Educational