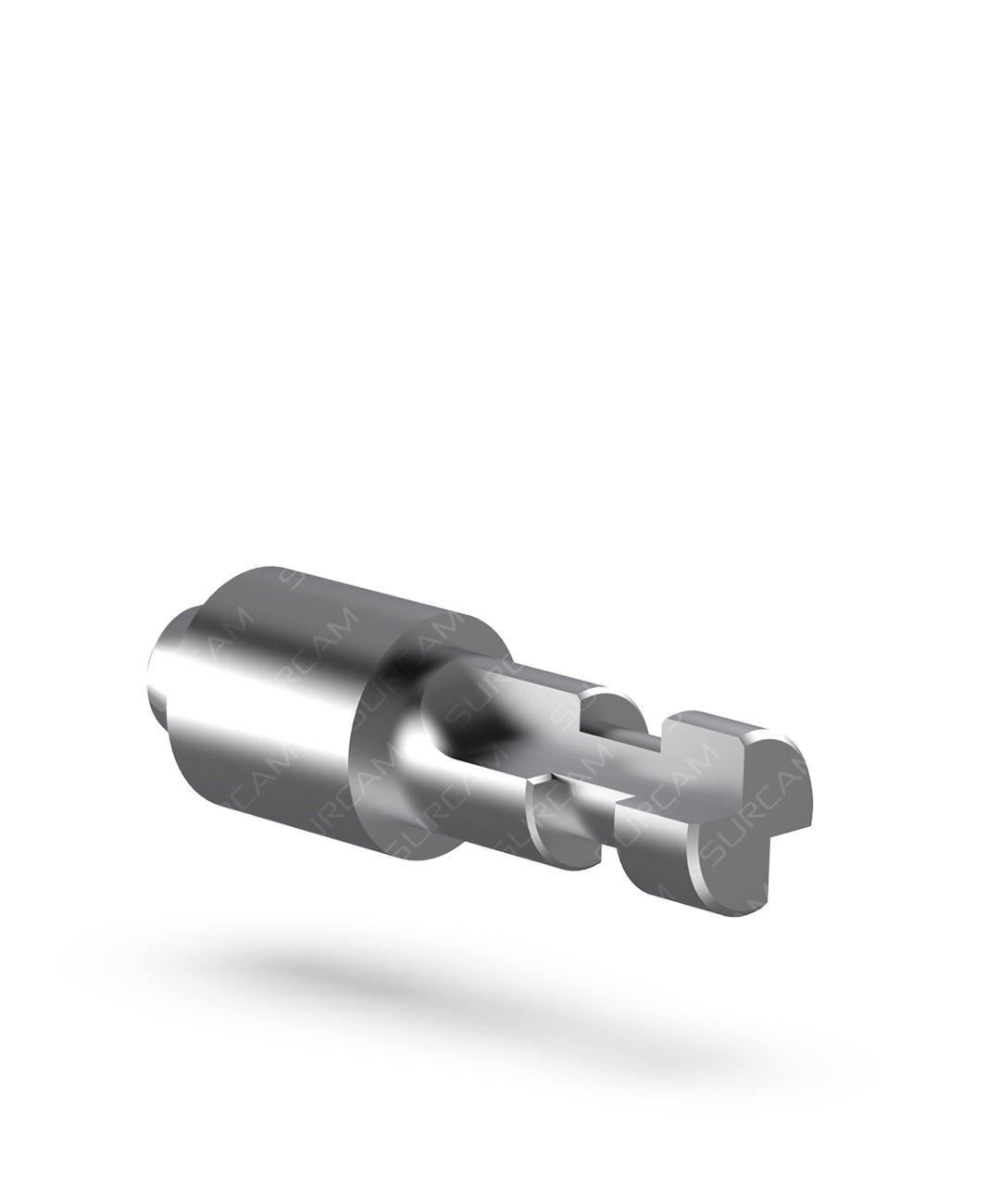

Product Details

Titanium lab analog for general Multi-Unit systems - accurate model indexing & stable seating

The Surcam Analog For General Multi-Unit replicates the multi-unit abutment interface in 3D-printed or milled models, enabling precise CAD/CAM fabrication of screw-retained provisional and definitive restorations. Machined from Titanium Grade 5 (Ti-6Al-4V), it delivers durable, repeatable indexing and seating that supports full-arch and segmental workflows with predictable fit.

Includes: 1× Analog.

Compatibility: General Multi-Unit system (verify geometry before use).

Benefits

-

Model accuracy – Tight tolerances help capture true position/angulation for passive frameworks.

-

Stable seating – Secure lock-in to printed/milled sockets reduces rotation during lab procedures.

-

CAD/CAM ready – Works seamlessly with IOS → design → milling for bridges and full-arch bars.

-

Durable titanium – Grade 5 construction withstands repeated lab handling.

-

Workflow versatility – Suitable for single, segmental, and full-arch situations.

Product Details

-

Interface: General Multi-Unit

-

Material: Titanium Grade 5 (Ti-6Al-4V)

-

Pack Contents: 1× Analog

-

Use: Laboratory/model use only (not for intraoral placement)

Specifications

-

Seats into 3D-printed or milled model sockets; verify full seating & rotational index

-

Follow your CAD/CAM library for socket dimensions and tolerances

-

Clean/inspect seating surfaces to maintain model precision

-

Compatible with standard screw-retained prosthetic workflows

Why Choose Surcam Analogs?

-

Consistent fit and indexing for predictable CAD/CAM outcomes

-

Grade 5 titanium longevity and dimensional stability

-

Smooth integration into modern digital lab processes

Surcam Analogs FAQs

Which systems is this analog compatible with?

General Multi-Unit interfaces. Verify the analog geometry against your multi-unit components before use.

Is this analog intended for intraoral use?

No. It is lab-only, for printed or milled models to support CAD/CAM fabrication.

Does it work with different 3D printers and resins?

Yes. It is printer-agnostic—use the correct library and ensure sockets are produced to specification.

How do I ensure accurate seating and indexing?

Confirm full seating and rotational index in the model socket; follow your library’s tolerances and lab protocol.

What prosthetics can be fabricated with this analog?

Screw-retained single units, short-span bridges, and full-arch frameworks produced via CAD/CAM from intraoral scans.